How to Calculate Reorder Points with the ROP Formula 2022

Average delivery lead time changes with fluctuations in seasonal demand, the quantity ordered, and distance from the up-chain supplier. For a reasonable measure, take an average of the past three months a beginner’s guide to business expense categories of POs for the SKU item you want to set a reorder point for. To accurately calculate reorder points, you’ll need to have strong records on sales volume and trends over a certain time period.

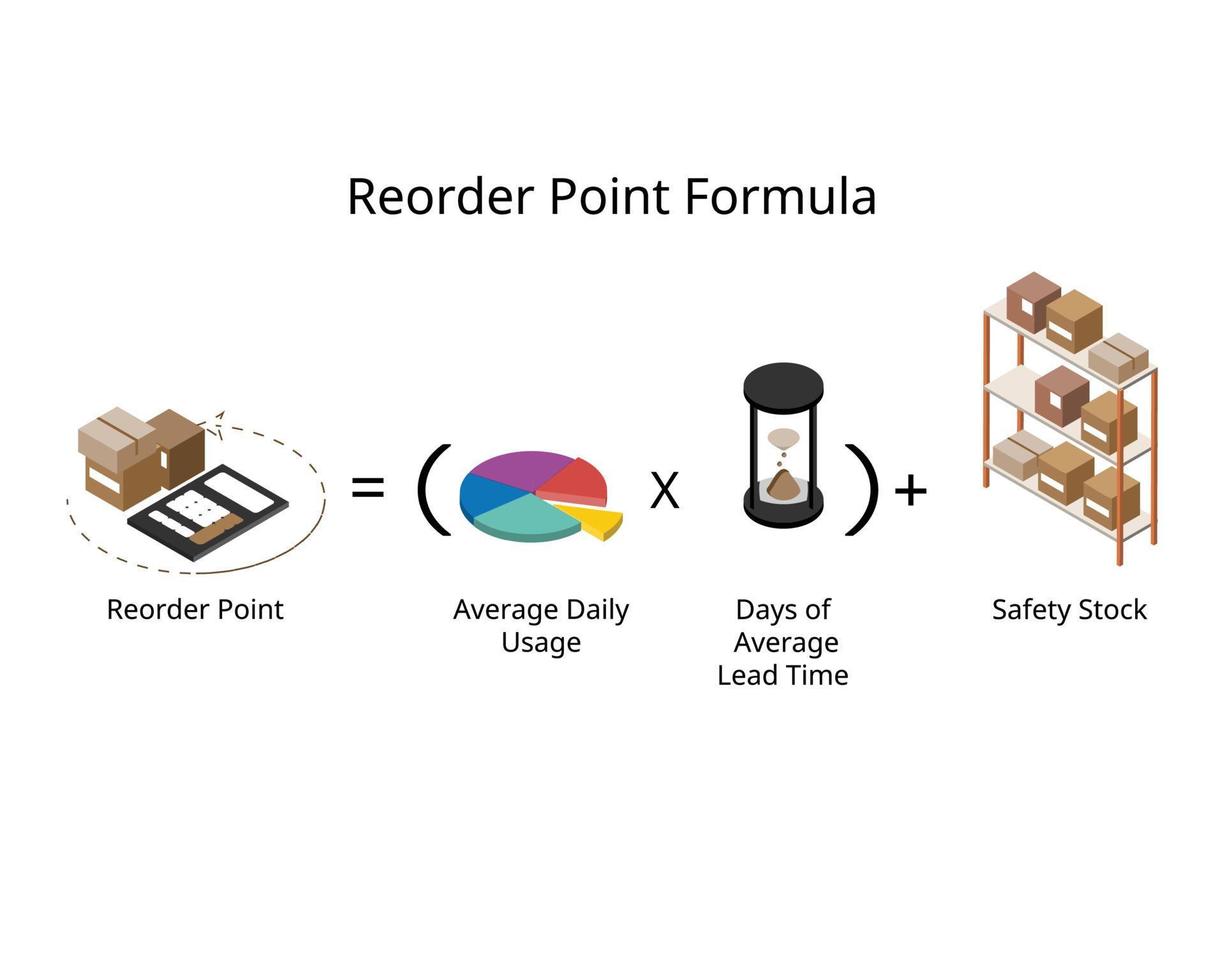

What is the Reorder Point Formula?

- To achieve these goals, the retailer should have business and analytics teams work closely to find the solution for their own scenario.

- Storing more inventory than what can be sold in a timely fashion is not a productive use of capital.

- In the complex realm of inventory management, the concept of reorder levels is paramount.

- This cyclic assessment helps sustain optimal inventory levels and prevents stock-outs or overstocking.

- Over those three months (or 92 days) that averages out to 1.5 units sold on average per day.

The minimum level, which is 1400 bottles, will help you fulfill your orders until your ordered stock reaches the warehouse. Once the new order is received in your warehouse, the stock level returns to the maximum level of 3400 bottles units. This guide will explain the fundamental steps to compute the reorder level effectively.

Types of Reorder Levels

Calculating ROP for each product can be time-consuming and challenging, especially if your inventory is patched together from several suppliers or you sell lots of products. ShipBob’s cutting-edge inventory management software and analytics tools make it easier than ever. While the basic concept of a reorder quantity remains constant, different approaches can be implemented based on a business’s specific needs and characteristics. Understanding these methods helps organisations choose the best inventory management strategy.

The reorder point formula in action

Note down significant dates that might impact your stock levels, including bank holidays, sales events like Black Friday, or even local festivals. Use these milestones to recalibrate your reorder thresholds ahead of time so you avoid having either too much or too little merchandise. To account for these fluctuations, keep a close eye on historical sales data. Adjust your average daily usage metric based on these insights, and consider implementing a more dynamic, data-driven approach to demand forecasting. In this scenario, reorder level would be 6,000 units (2,500 of safety stock plus 3,500 units based on 7 days of lead time).

Key Differences Between Re-Order Level and Re-Order Quantity

Let’s look at how to calculate a reorder point both with and without safety stock. Then we’ll cover how to handle reorder points when you have multiple vendors. ShipBob’s platform doesn’t just help with inventory control and forecasting, but generates powerful analytical reports covering all areas of your business. You can get inside the numbers and find new ways to improve supply chain efficiency.

How confident are you in your long term financial plan?

First you want to determine your demand during lead time by multiplying your daily sales by the lead time. It works best when you have a reliable supply chain and good relationships with your suppliers. Similar to demand, the FOP assumes that your lead time for items bought from the supplier is consistent throughout the year.

The longest time it would take the supplier to deliver this component is 15 days. And let’s assume that the average daily use is 1.5 units, and the average lead time is 12 days. You may purchase items in your inventory from various vendors, and different vendors have different lead times. Therefore, it’s best to think of your reorder point on an individual item level.

For example, real-time inventory tracking allows staff to see what’s in stock, what’s on order, and where each item is located. Software tools can also collect and present data on purchase orders, sales fulfillment, and demand forecasting on a single user dashboard. Regularly calculating reorder points removes the mystery from inventory cost control and helps your business maintain optimal service levels. The reorder point is the minimum number of units a company needs to have in stock to fill sales orders or meet production targets. Once inventory dips below the calculated reorder point, replenishment is triggered through a new purchase order.

In contrast, periodic review systems check inventory at fixed intervals (e.g., weekly, monthly) and order if levels are at or below the reorder point. If your stock levels are too high, you’ll need to scale up your warehousing storage capabilities. Businesses with a limited number of products can start with excel spreadsheets and format cells to turn red when inventory levels reach the reorder point.

In this retailer’s guide to reorder points, you’ll learn everything you need to know to set effective reorder points and much more. Sourcetable is designed to meet the needs of anyone looking to deepen their understanding of mathematical concepts or enhance their professional workflow. Its ability to explain complex calculations in simple terms makes it an excellent resource for students and professionals alike. Whether you’re preparing for an exam or managing a business, Sourcetable provides the tools you need to succeed. Meredith is a Content Marketing Specialist at ShipBob, where she writes articles, eGuides, and other resources to help growing ecommerce businesses master their logistics and fulfillment. By using the reorder point formula, you know that when your inventory reaches 175 red bandanas, you need to replenish your inventory so you don’t experience shortages.